Banshuori

(Producing process)

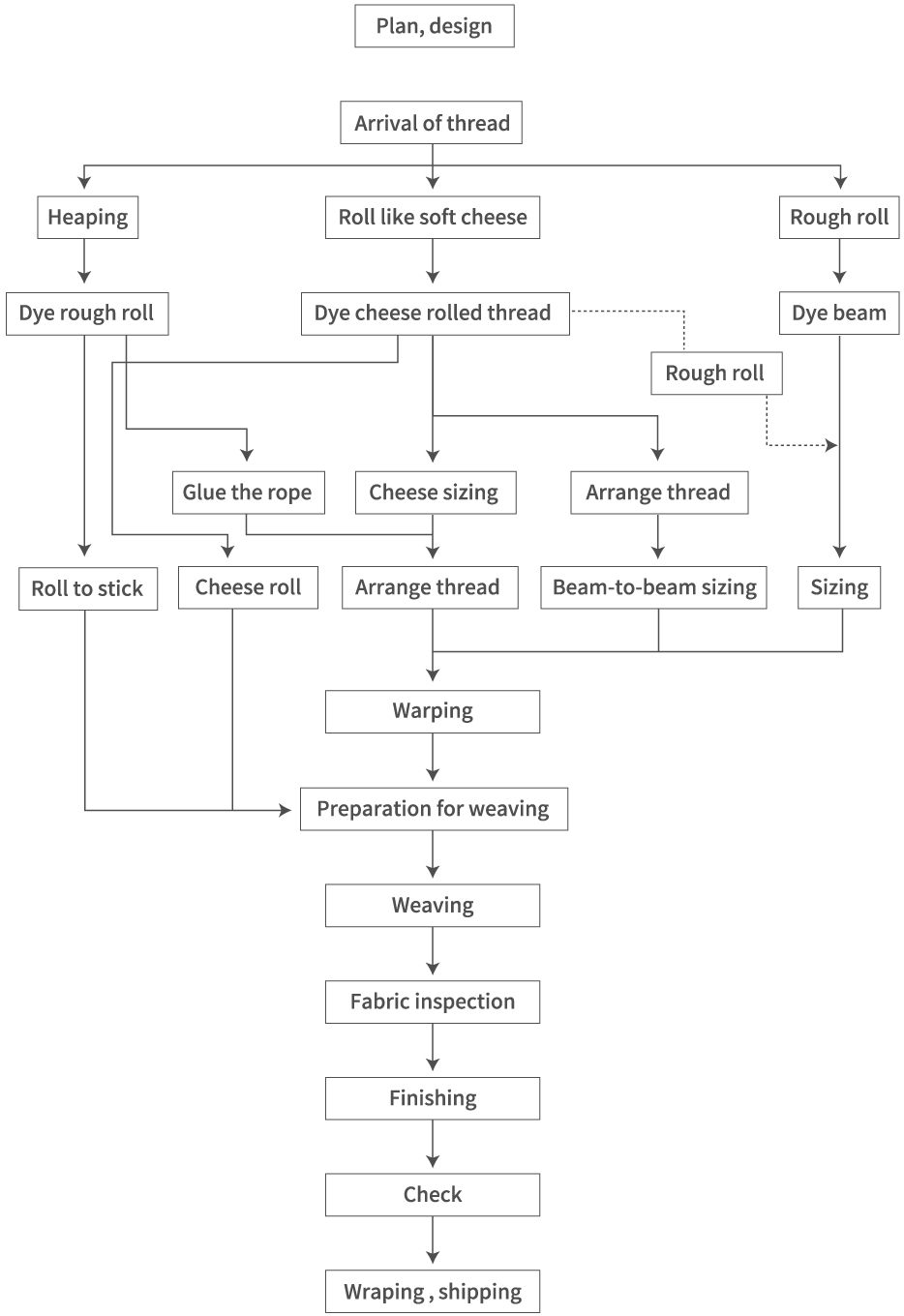

Producing process

-

Plan, design

(Plan)

Plan for products according to the usage of textile -

(Textile design)

Design clothes or interior by color, pattern, painting and texture. -

(Sample room)

Showroom of agents. There are many samples here and it plays an important role in the development of products. -

Arrival of thread

Various fibers such as natural fibers, functional fibers and eco fibers are shipped to the producing area.

-

Heaping

The process that rolls thread by determined times to a stick before dyeing.

-

Dyeing

Dye the sticks in a dyeing tank.

-

Roll like soft cheese

To dye better, roll the thread in a shape like a soft cheese roll.

-

Dye cheese rolls

Put the soft cheese shaped rolls into dyeing tank to dye.

-

Re-roll thread

Re-roll the thread in a shape of cheese or corn to fit the rapier looms or air jet looms.

-

Arrange thread partly

Arrange the glued thread in a machine.

-

Beam-to-beam sizing

Size the arranged thread.

-

Rough roll

The process to roll thread to a dyeing beam. Thousands of thread with the same length would be rolled at the same time.

-

Dye beam

Put the rough rolls into a tank for dyeing. This is suitable for dyeing big lots.

-

Sizing

Size the determined colors or patterns.

-

Wiring

Put thread though the sized beams.

-

wiring

-

Leading thread

Put thread though the leads.

-

Leading thread

-

Preparation for weaving

Put prepared beams to the loom.

-

Weave (air loom)

Use cam or tappet to move heddles up and down. Usually within 8 heddles.

-

Weave (rapier)

Use dobby to move heddles up and down. Usually within 16 heddles.

-

Weave (jacquard)

Use jacquard to move thread up and down.

-

Fabric inspection

Inspect the fabric.

-

Finishing

Process the materials weaved in factories.

-

Finishing

Do the final check.

-

Wrapping

Wrap products that meet the standard.

-

Ship the products.

Ship the products.